Market Trends of Syringe Filling Machine Industry

This section covers the major market trends shaping the Syringe Filling Machine Market according to our research experts:

Increased Shelf Life and Reduction Of Wastage

- It is estimated that the medication stored inside of a prefilled syringe cartridge will remain sterile for approximately two to three years when compared to a standard syringe which can be sterile for only 12 hours when filled. Also, the prefilled syringes have lesser overfill when compared to manual filling. It is estimated that for a 0.5 ml vial, the USP recommends 20-25% overfill. In contrast, for 0.5 ml, the required overfills are less than 2%. As a result, potentially 18-23% more doses can be produced.

- Also, With the increasing technological disruptions taking place across industries, owing to the wide-adoption of Industry 4.0 and automation amongst others, the pharmaceutical industry is adopting new and effective methods of drug creation. Pharmaceutical syringe filling equipment allows companies to streamline the syringe packing process as these are capable of filling up to hundreds of syringes per minute.

- The pharmaceutical syringe filling equipment maintains longer sterility and provides precise, automated control over barriers, tips, and additional accessories required for syringes. Moreover, the manufacturers can bring the the overal cost down with the help of high output pharmaceutical syringe filling machines.

- In March 2019, the pharmaceutical packaging company Schott Kaisha expanded its capacity to manufacture vials, pre-filled syringes, and sterile solutions. The company’s expansion plans include new sites in Gujarat and North India, along with the expansion and up-gradation of existing plants in Daman and Jambusar in Gujarat. These developments are expected to augment the market growth in the emerging economies as the pharmaceutical companies start adopting these machines for their drug creation.

- The market is witnessing a rising need for infused product manufacturers for sufficient filling machinery for CBD and THC products. The CBD oil cartridges require filling equipment that can provide detailed parts, and simple changeover, and cleanup, quick turnaround, among other factors, due to which pharmaceutical companies have been more inclined towards syringe filling machine for CBD applications.

- In February 2019, Optima Pharma introduced its MultiUse filler machine designed to process different types of containers in a flexible and fully automated way. Optima’s MultiUse Filler fills vials, syringes, and cartridges with one machine and allows for small batch sizes and different container types. These initiatives by various pharmaceutical companies will further stimulate market growth.

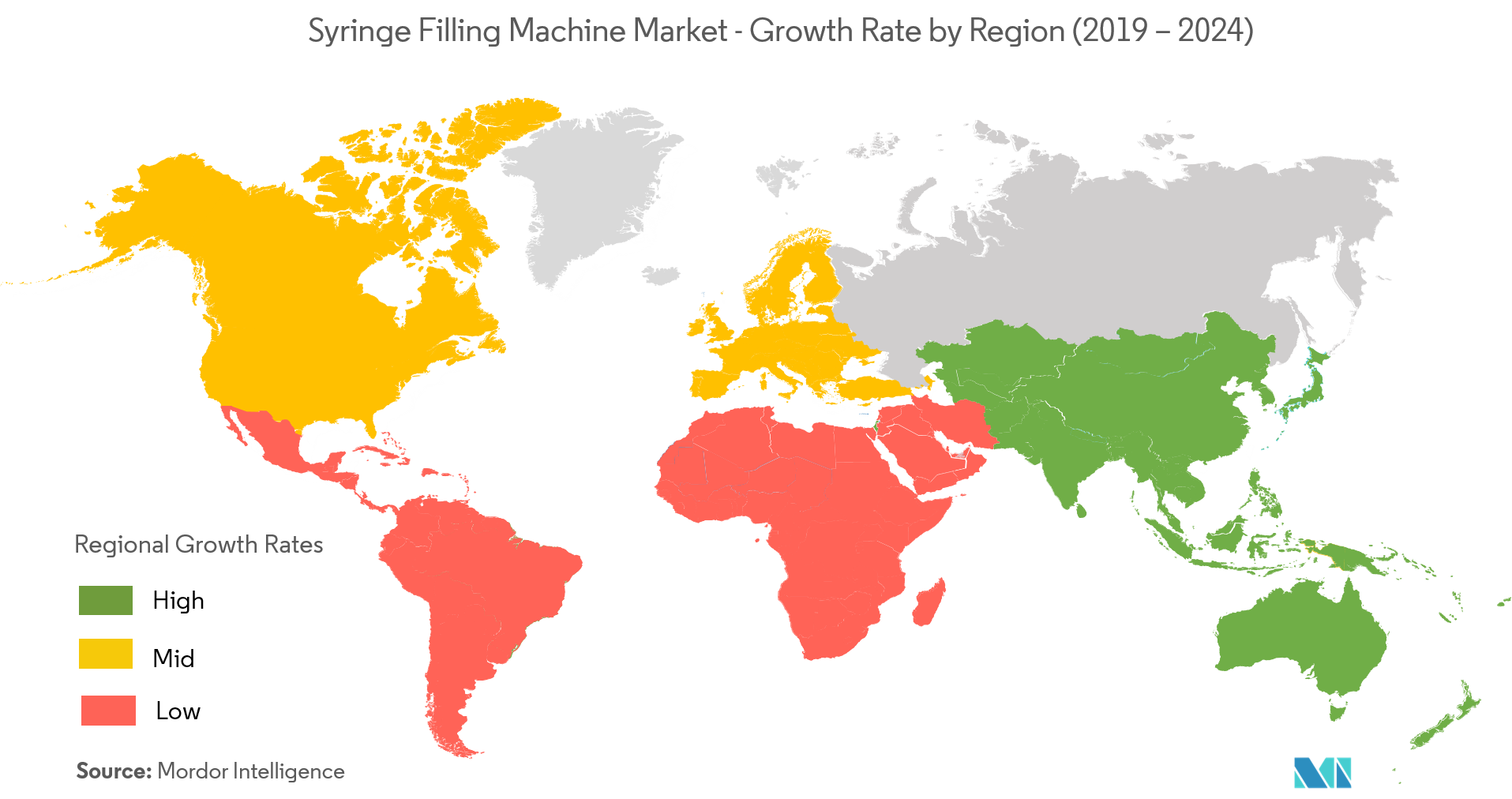

North America is Expected to Hold Significant Share

- The CDC, FDA, and NASEN are the main regulatory bodies in the North American region. These regulatory bodies have been increasingly promoting the safety of the patients that are administered with vaccines. The prefilled syringes are going to play an important role in the administration of the vaccine in the US as there are rising concerns about the overdose of vaccines administered to children.

- Furthermore, this region has seen significant developments in the syringe filling machines, most recently NC-based Mission Health in Asheville, installed two RIV automated IV compounding systems from ARxIUM that sterile-fill liquids and lyophilized products into IV syringes, and bags for administration to Mission Health patients.

- Also, The increasing number of chronic diseases in the region that require frequent vaccine usage is one of the prominent factors contributing to the growth of the market over the forecast period. According to the hepatitis B foundation, Up to 80,000 Americans will become newly infected with Hepatitis B each year, and more than 2 million Americans are chronically infected. More and more manufacturers in this region are getting approval for prefilled syringes for Hepatitis B vaccines. Dynavax was one of the major pharma company to receive FDA approval for their pre-filled syringe vaccine HEPLISAV-B in March 2018.

- The technological advancements in the region in terms of robotics is one of the prominent factors that would drive the growth of the syringe filling machine in the region. For instance, FP Developments that provide syringe filling and handling, vial filling and handling, mark and verify, track-and-trace, unique device identification (UDI) uses a Universal Robots UR-3 robotic arm to perform aseptic syringe filling and capping.