Market Trends of Mexico Automotive Parts Aluminum Die Casting Industry

This section covers the major market trends shaping the Mexico Automotive Parts Aluminum Die Casting Market according to our research experts:

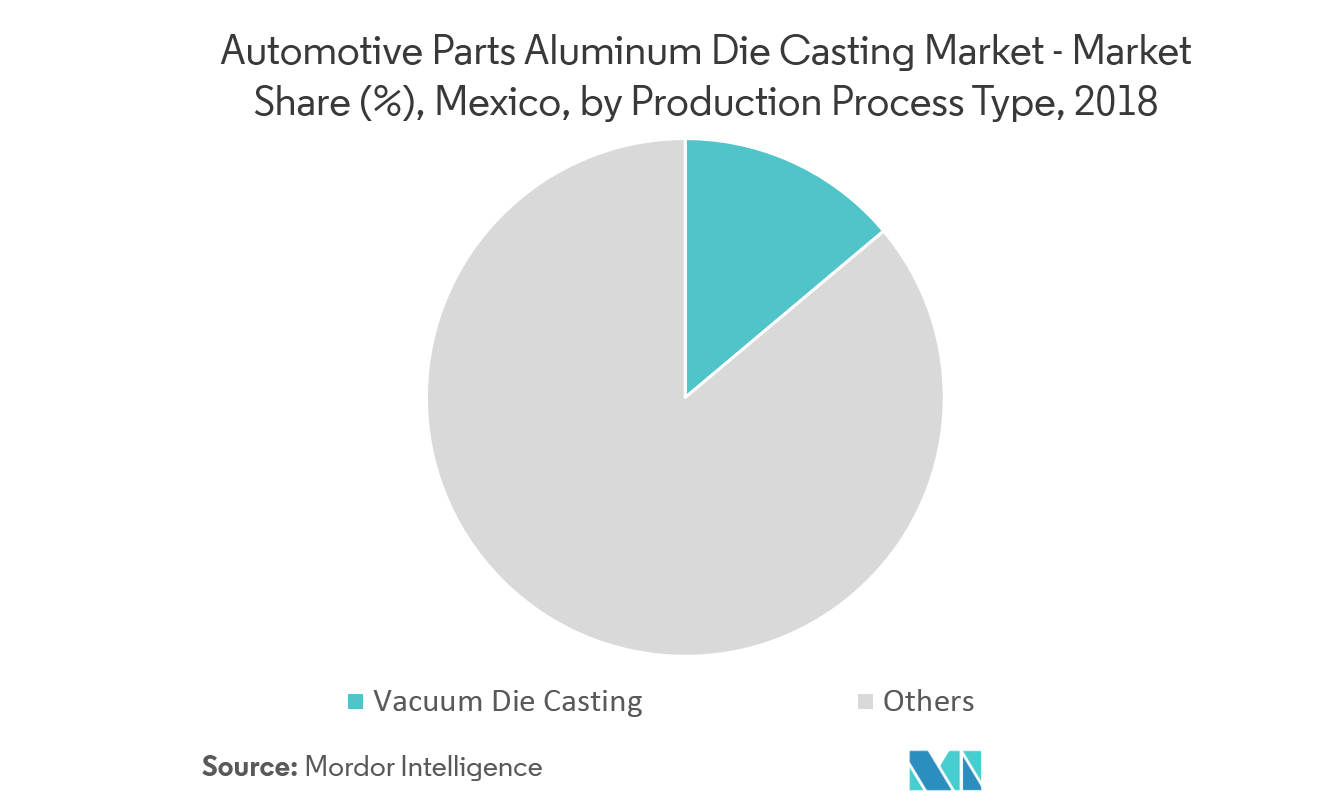

Vacuum Die Casting Process Growing at a Higher CAGR

There have been significant developments and improvements in the conventional die casting process. Currently, the ultra-high-vacuum die casting process is applied for producing large and thin component parts, such as space-frames and pillars, which are usually welded to automobile chassis.

Electrical and hydraulic components in an automobile, work simultaneously. Reliability and quality are given prime importance in transmission parts. The transmission system in an automobile is a complex combination of mechanical functions. It is prone to extreme conditions and environments. This enhances the importance of integrity. Valve bodies, stators, and clutch pistons are some of the commonly die casted transmission parts in the automotive industry.

It has been accepted that, ultra-vacuum die casting produces better weldable automotive products than most of the die casting processes. However, products produced in this process are large and require huge-sized die casting machine, like 2,500-4,000 metric ton of die clamping force. This impacted the popularity of the ultra-high-vacuum die casting process among OEMs and large die casters.

However, vacuum die casting production process eliminates the air from the mold and allows the front of molten metal to merge freely without forming any shuts or pores, which is major issue in pressure die casting process.

A sudden shift from pressure die casting to vacuum may not be possible due to the higher productivity and ease of manufacture of the automotive die casting parts, which employ pressure die casting method. However, this change is gradual and expected to continue to increase, during the forecast period.

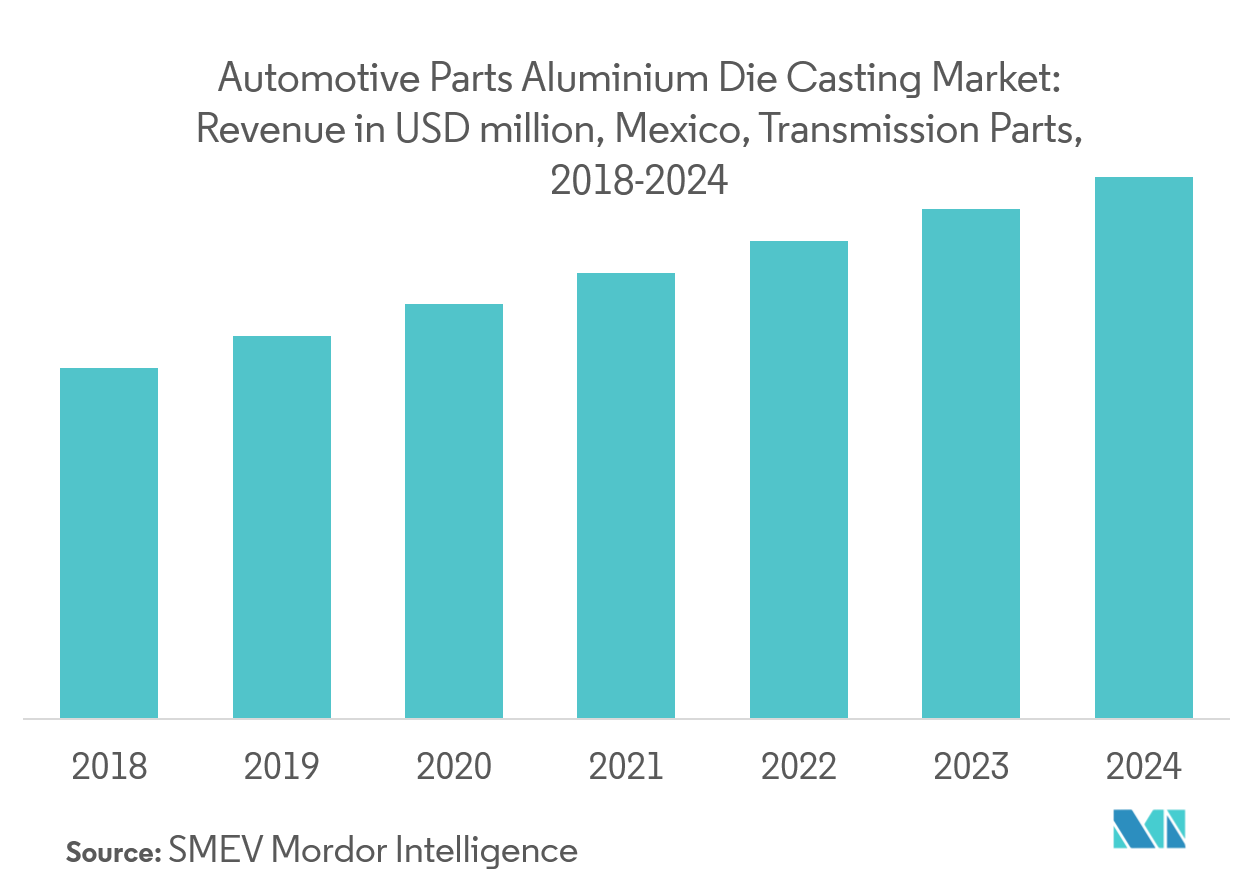

Increase Adoption of Aluminum in Transmission Parts

Electrical and hydraulic components in an automobile work simultaneously. Reliability and quality are of utmost importance in transmission parts. The transmission system in an automobile is a complex combination of mechanical functions. It is prone to extreme conditions and environments, making the integrity a very high priority. Valve bodies, stators, and clutch pistons are some of the commonly die casted transmission parts in the automotive industry.

Employing vacuum has become the latest trend in the manufacture of transmission valve bodies, in order to restrict the porosity to the minimum. Blue Ridge has come up with a complex turbine with vanes, optimized for efficient fluid flow. This construction structure provides a seal, capable of both die expansion and controlling pressure of molten metal between moving members of the die, for a better end product.

Die casters are found to employ advanced die design, along with utilizing simulation techniques and power venting systems. These, coupled with thermal analysis of the die casting, are expected to produce clutch pistons catering to the specific concerns of piston use and assembly.