Market Trends of Safety Sensors Industry

This section covers the major market trends shaping the Safety Sensor Market according to our research experts:

Automotive End User Hold a Significant Market Share

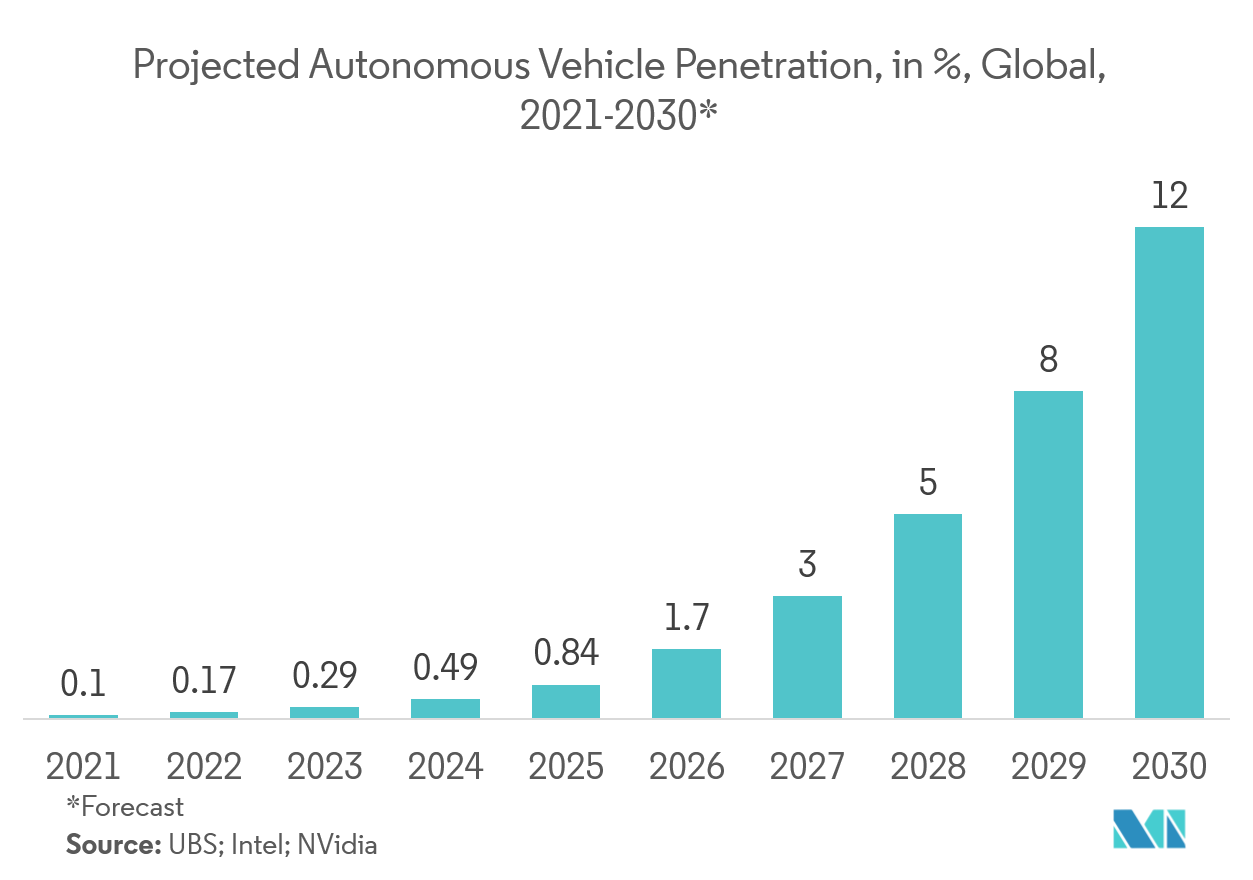

- The automotive industry is the fastest growing end-user segment for safety sensors. The increased usage of automation solutions and the production of autonomous vehicles are the key driving factors for growth in demand form this sector.

- Traditionally, safety sensors such as light curtains and safety mats are popular amongst the automakers for a long time now. But as the manufacturing establishments had evolved over time, there has been an increased demand for advanced safety sensors that take robotic solutions used in the assembly line into account.

- It is estimated that in the same year, the automobile industry consumed about 38% of the total supply of industrial robots. It is estimated the usage of new materials such as carbon fiber, increased production of electric cars and high competition in all major car markets will push the manufacturers for investments into industrial robots despite the existing overcapacities.

- Apart from increased automation, high rate of accidents in the manufacturing and servicing establishments of the automotive sector is another primary driver for the need for smart sensors in this sector.

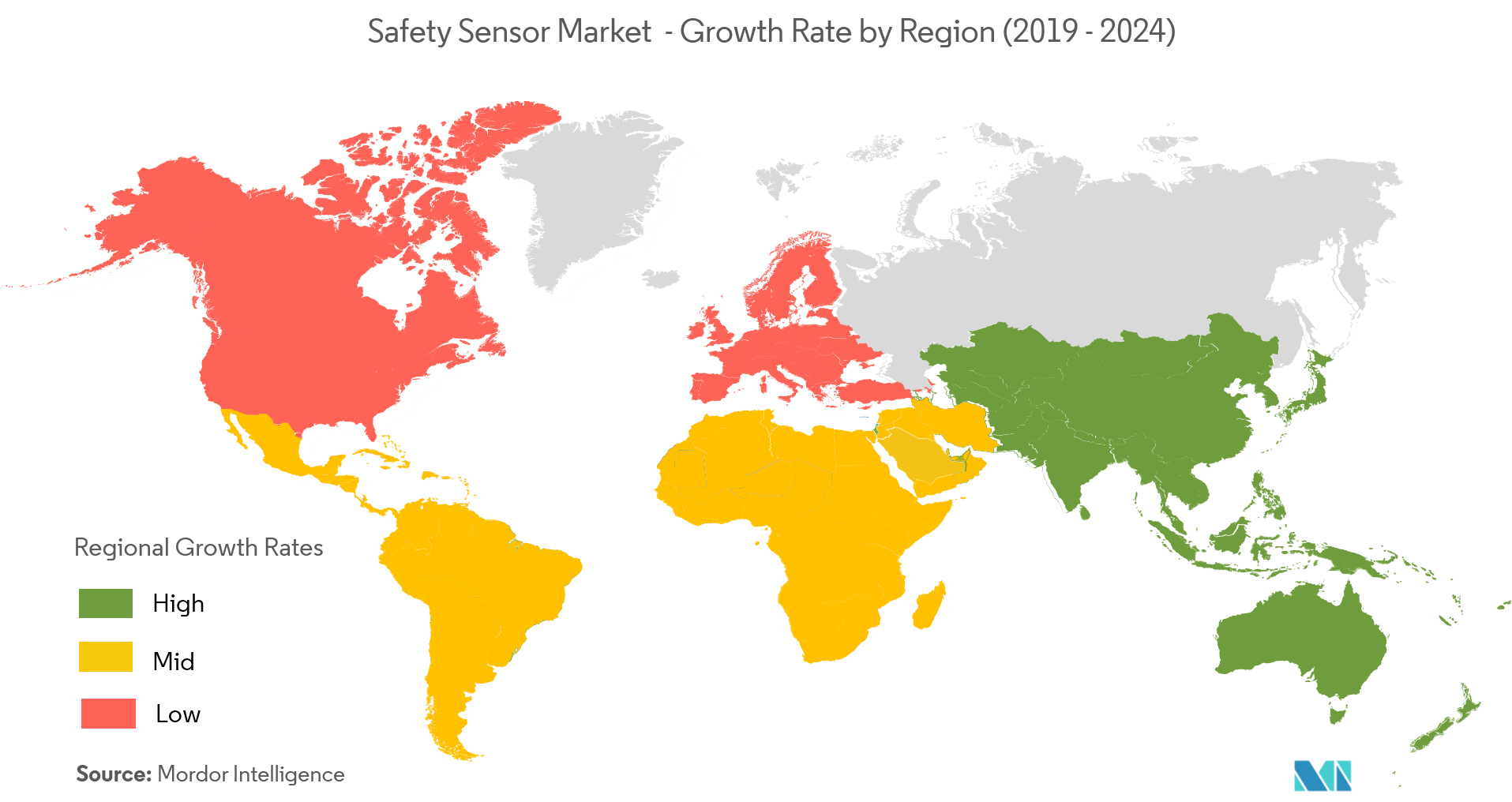

North America Account for Significant Market Share

- In North America, the manufacturing industry is thriving, offering employment to over 12 million people, thus leading to USD 6 trillion nominal gross domestic product in the first quarter of 2017 alone and is expected to grow in the forecast period.

- New technologies, such as safety sensors, are already playing their part in making factories more efficient, cost-effective, safe, and easier to manage. The move towards greater automation is the unavoidable flow of change.

- The US Department of Labor Occupational Health and Safety Administration (OSHA) oversees requirements that make workplaces safer. However, The challenge remains in changing the approach to workplace safety by emphasizing prevention instead of detection. By including safety sensors in the factory assembly line, proper preventive measures are being taken.

- Since 1950, safety mats have been the standard form of area protection in the factories throughout North America. However, safety mats are subject to physical and environmental abuse and can wear out with repeated long-term use. Nevertheless, safety mats are widely used in modern automated factories throughout the United States.